Engineering Material Testing

Al Ghalowa Provides a wide range of inspection equipment for welding, Destructive & Non-destructive tests for the materials used in the construction of Oil industries processing units.

- Pipeline network and steel structure Fabrication and Erection

- Welding and NDT

- Surface protection and Coating

Teledyne CP series

With miles upon miles of welded pipelines, hundreds of gas tanks and thousands of pressure vessels to inspect, the Oil & Gas industry requires ruggedized high-class quality control equipment able to do the job in record time while being robust and long-lasting. With generators going up to 300 kV, the CPSERIES family truly embodies the ideal Oil & Gas x-ray generator.

the SITEX CPSERIES generators feature a shutter, a laser pointer, a beryllium window, an aluminium filter and two integrated diaphragms (customized sizes are available upon request). Without compromising the robustness and reliability for which ICM products are renowned, the small size and light weight of the SITEX CPSERIES will radically change the way that you perform your RT inspections. And you will see a positive impact in terms of both quality and return on investment (ROI).

Mobile Metal Analyzers

The SPECTROTEST is a mobile arc spark spectrometer ideal for many applications in the metal producing, processing, and recycling industries. This mobile metal analyzer flaunts its superior performance especially when exact metal analysis is required, when materials are difficult to identify or when there is a large number of samples to be tested.

SPECTRO xSORT

The SPECTRO xSORT family of handheld ED-XRF spectrometers supplies elemental testing and spectrochemical analysis of myriad materials in widely varying conditions. These energy dispersive X-ray fluorescence devices are recognized for ruggedness and reliability on the job. They offer metals or nonmetals identification in seconds, with innovative technologies and designs that provide repeatable, laboratory-quality results. Simple, user-friendly displays and efficient ergonomics make these instruments extremely easy to use. At a range of affordable prices, SPECTRO xSORT spectrometers are leaders in their class for a broad spectrum of applications.

Metallographic sample preparation

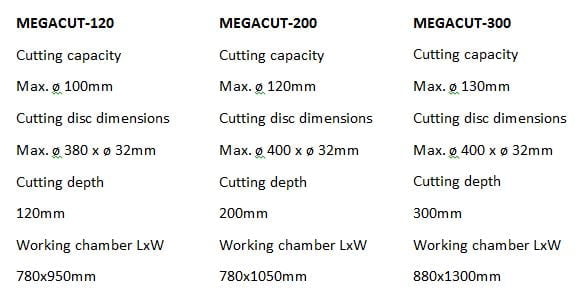

cutting machine

Automatic/manual floor-type metallographic cutting machine, equipped with PLC control and touch screen for displaying cutting data and samples positioning cutting table provided with T-slots to assemble different vices the cutting chamber is equipped with an internal ventilation system to increase the visibility during the process. It is supplied with 70 liters cooling system Built-in safety features; internal safety device allows operation only if the cutting chamber is closed Suitable also for cutting rocks and ceramic materials using

diamond cutting discs This series is suitable for quality control, scientific research institutes and universities.

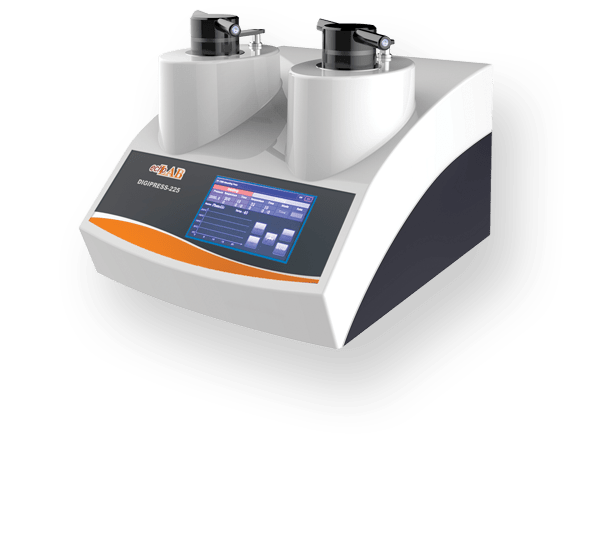

MOUNTING PRESS MACHINES

Automatic mounting press with large size LCD touch screen, microprocessor controlled for setting all processparameters such as, automatic pre-heating, heating, working pressure, cooling time one cylinder with intermediate piston which makes possible to carry out 2 mounting operations at same time different mold sizes available (ø 25mm, ø 32mm, ø 40mm,ø 50mm), two sizes can be selected Automatic water cooling system.

Grinding polishing machines

Automatic and Manual double platen grinding/polishing machine, fully programmable by LCD touch screen control panel Platen ø 250mm or ø 300mm DC brushless motor, stepless speed Cooling system to prevent sample.Overheating recommended for scientific research institutes, metallographic laboratories and universities.

UNIVERSAL HARDNESS TESTERS

UNIVERSAL HARDNESS TESTERS

Digital Brinell, Rockwell & Vickers Hardness Tester Digital Brinell, Rockwell & Vickers hardness tester equipped with large displaying screen. Three test modes and 7 level of test forces, test force loading, dwell, unload adopts automatic shifting. Present scale, test force, test indenter, dwell time and hardness conversion displayed. With RS232 interface for computer connection. Suitable for hardened and surface hardened steel, hard alloy steel, casting parts, non-ferrous metals, various kinds of hardening and tempering steel and tempered steel, carburized steel sheet, soft metals, surface heat treating and chemical treating materials etc.

QNESS UNIVERSAL HARDNESS TESTER

VERSION CS/C EVO

The new Brinell / Knoop / Rockwell / Vickers hardness tester series EVO by QATM combines extremely short cycle times with maximum precision

The characteristic “C” shaped machine frame gives the CS and C versions of the Qness 250/750/3000 EVO series their name.

Brinell

DIN EN ISO 6506, ASTM E-10

HBW 1/1 HBW 1/2.5 HBW 1/5 HBW 1/10 HBW 1/30 HBW 2.5/6.25 HBW 2.5/15.6 HBW 2.5/31.25 HBW 2.5/62.5 HBW 2.5/187.5 HBW 5/25 HBW 5/62.5 HBW 5/125 HBW 5/250 HBW 10/100 HBW 10/250 HBT (not acc. to standards

Vickers

DIN EN ISO 6507, ASTM E-384, ASTM E92

HV 1 HV 2 HV 3 HV 5 HV 10 HV 20 HV 30 HV 50 HV 100 HVT (not acc. to standards)

Rockwell

DIN EN ISO 6508, ASTM E-18

HRA – HRV HR15-N/T/W/X/Y HR30-N/T/W/X/Y HR45-N/T/W/X/Y

Knoop

DIN EN ISO 4545, ASTM E-92, ASTM E-384

HK1 HK2

Plastics

DIN EN ISO 6507, ASTM E-92, ASTM E-384

49.03 N 132.9 N 357.9 N 961 N

Integrated conversions: DIN EN ISO 18265, DIN EN ISO 50150

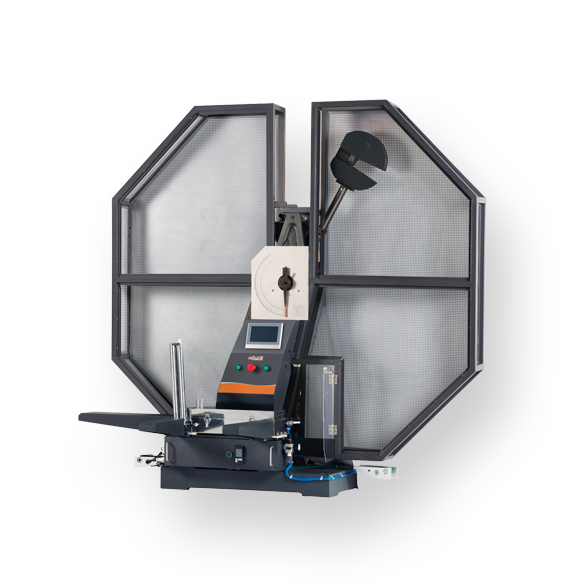

IMPACT TESTING MACHINES

ITM-S series impact tester for metal and other materials, fully complying to ISO 148, EN 10045, ASTM E23, GOST 9574 with impact energy ranging 150J, 300J, 450J, 600J and 750J.One-body cast frame design structure provides high stability and rigidity. Front and rear columns are symmetrical and pendulum arm is designed as cantilever beam support. ITM-S series is equipped with small friction high precision bearings. Absorbed energy without loading less than 0.3%. Double reduction gear system replaces the old drive system with high efficiency avoiding transmission failure Heavy solid steel base machine structure for anvil and heavy-duty cast steel uprights supports. Structure designed to change different pendulums easily. Impact testing machines equipped with electromagnetic hammer release system and clutch for locking and raising to initial position, dumper to prevent strong bump. ITM-HF series equipped with Siemens PLC for tester controls and with high precision rotary encoder NEMICON, to measure the angle with resolution of 0.025° to ensure high accuracy of impact energy.

universal testing machine

universal testing machine

Servo-hydraulic universal testing machine

HTM series

HTM double column series, from 200kN to 2000kN. Designed with strong structure to ensure the linear

crosshead travel. High accuracy crosshead alignment reducing variability in measurement. HTMs from 200kN to 2000kN are dual space type. Wide range of test accessories allows to meets test requirements of different standards and for different materials. HTM series is suitable to test: metals, reinforced plastics, wires, composite materials.

Electromechanical Testing Machines

Electromechanical Universal Testing Machines ETM series includes complete range of electromechanical Universal Testing Machines, from the compact and lightweight single column torobust double column floor-standing version. Equipped with load cells from 0.5 to 600kN, ETM series allow to perform wide range of tests on different kind of materials such as: metals, plastic, composites, wood, wires, biomaterials etc. Pre-loaded ball screws, heavy duty bearings and full protection covers,ensure long life with zero backlash. The result is an accurate and repeatable measurement which represents the specimen characteristics Aluminum column covers with chamfered corners for easy access to the test area, T-slots for easy positioning of testing accessories ETM series is equipped with high-speed and low vibration AC servo motor and servo controller, Japanese photoelectrical encoders for displacement measurement American bi-directional load cells positioned in the middle of crosshead to prevent any collisions during to tension or compression tests High speed and closed loop controller of load displacement and elongation, with over-load, over-current, over- voltage, over-speed, and over-travel protection.All models supported by test software to show and analyses graphs and all tests parameters. X-MET8000 Handheld Analyzer

X-MET8000 Handheld Analyzer

Versatile materials analyzer

Testing a vast range of materials – solids, powders or liquids – the X-MET8000 is ideal for analyzing metals, soils, wood, plastics, glass, oils and more. The analysis is non-destructive and leaves no test mark.

Anyone can work it anywhere

Lightweight, compact and portable, the X-MET8000 is operated by an icon-based touch-screen and comes pre-calibrated for many applications. Easy to use and its military-grade durability is more than a match for the dirtiest, hottest and most hostile environments. In addition, an optional window shield can protect the detector from sharp and rough materials.

Precision in an instant

X-MET8000 can provide results on site in seconds, depending on the application. Phenomenal reliability and speed, with no requirement to return for lab assessment, mean optimum productivity, lower costs and an all-important edge over your competitors. Data can be stored on the analyzer, on a USB flash drive, or through our app and cloud service for immediate sharing.

CORROSION Lab

CORROSIONBOX H

Horizontal test chambers with clear cover for salt spray, condensation tests and cyclic corrosion tests.Available in 5 models: from 600 to 2000 liters , Special dimensions available on request

CORROSIONBOX ENHANCED SALT SPRAY CHAMBER

Chamber for continuous salt spray and condensation test and cyclic tests. Features: strong structure all 10 mm thickness polypropylene construction with built in 160 litres salt solution reservoir. Clear cover for easy viewing of test condition, cover is peaked to prevent dripping on samples. Access to test chamber with pivoting cover with water seal. Spray nozzle full made in plastic material, suitable for AASS and CASS tests. Humidifying tower with automatic water level restoring system and temperature-controlled water heater. Peristaltic pump for salt solution dosage. Pressure regulator for control of nozzle air pressure. Dedicated microprocessor control panel with 4 lines of 20 characters. All function of chamber is controlled or monitored: chamber and humidifier temperature controlled and monitored, nozzle air pressure and dosing pump speed monitored, all anomalies are signaled. Free programming and storing of 15 test programs, complete test report is edited for each test, RS232 serial interface for serial printer or pc connection. Air and water filter to be installed on supply lines. 6 bars and 4 standard specimen holders.